Trending...

- Purple Heart Recipient Honored by Hall of Fame Son In Viral Tribute Sparking National Conversation on Service Fatherhood, Healing and Legacy

- Lineus Medical's SafeBreak® Vascular Added to Alliant GPO Contract

- VENUS Goes Live on CATEX Exchange As UK Financial Ltd Activates The Premier Division Of The Maya Meme's League

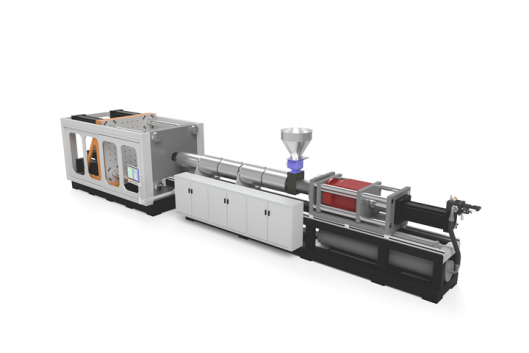

WILMINGTON, N.C. - ncarol.com -- Wilmington Machinery, a leader in the design and manufacture of large structural foam machines, is streamlining delivery times for its Low-Pressure Structural Foam machines. While typical lead times for these large machines can range from 9 to 15 months, Wilmington has significantly reduced this wait with in-stock and nearly completed machines available for quick delivery.

Currently available is a 500-ton Low Pressure Structural Foam machine featuring a 50lb shot and a spacious 70" x 80" platen. This machine is ready for shipment within 3-4 weeks of purchase order receipt. In addition, Wilmington is building another 500-ton machine, this one with a larger 100lb shot capacity and an even bigger 96" x 90" platen, which will be available for delivery by May 2025.

Both machines are versatile and can be customized with options such as robotic part removal, gas assist controls, and core pull manifolds, allowing for a tailored solution to fit various production needs.

More on ncarol.com

"By having machines in stock and under construction, we can offer manufacturers a faster path to upgrading their production capabilities," said Jim Boos, VP of Sales & Marketing of Wilmington Machinery. "These machines deliver superior structural foam molding capabilities, and with quick delivery options, we're supporting customers in reducing lead times and getting to market faster."

For more information about Wilmington Machinery's Low Pressure Structural Foam machines or to inquire about customization options, please contact us at wilmingtonmachinery.com.

About Wilmington Machinery Wilmington Machinery has been a trusted name in manufacturing machinery for over 50 years, specializing in plastic processing solutions. Their innovative technology and expertise have provided industries with state-of-the-art machinery for injection molding, extrusion, and structural foam molding.

Currently available is a 500-ton Low Pressure Structural Foam machine featuring a 50lb shot and a spacious 70" x 80" platen. This machine is ready for shipment within 3-4 weeks of purchase order receipt. In addition, Wilmington is building another 500-ton machine, this one with a larger 100lb shot capacity and an even bigger 96" x 90" platen, which will be available for delivery by May 2025.

Both machines are versatile and can be customized with options such as robotic part removal, gas assist controls, and core pull manifolds, allowing for a tailored solution to fit various production needs.

More on ncarol.com

- National Expansion Ignited Across Amazon $AMZN, Chewy $CHWY & Walmart $WMT: NDT Pharmaceuticals, Inc. (Stock Symbol: NDTP) $NDTP

- Distributed Social Media - Own Your Content

- Tarrytown Expocare Pharmacy Announces Strategic Leadership Appointments to Accelerate Growth and Innovation

- New Environmental Thriller "The Star Thrower" Reimagines a Classic Lesson in Individual Impact

- Summit Appoints Javier Cabeza as Data, AI, and Analytics Practice Lead

"By having machines in stock and under construction, we can offer manufacturers a faster path to upgrading their production capabilities," said Jim Boos, VP of Sales & Marketing of Wilmington Machinery. "These machines deliver superior structural foam molding capabilities, and with quick delivery options, we're supporting customers in reducing lead times and getting to market faster."

For more information about Wilmington Machinery's Low Pressure Structural Foam machines or to inquire about customization options, please contact us at wilmingtonmachinery.com.

About Wilmington Machinery Wilmington Machinery has been a trusted name in manufacturing machinery for over 50 years, specializing in plastic processing solutions. Their innovative technology and expertise have provided industries with state-of-the-art machinery for injection molding, extrusion, and structural foam molding.

Source: Wilmington Machinery

0 Comments

Latest on ncarol.com

- Custom Wooden Token Manufacturer Celebrates 10 Years of Helping Brands Stay Top of Mind

- NaturismRE Launches the NRE Health Institute to Advance Evidence-Informed Public Health Research

- P-Wave Classics to publish Robert Bage's Hermsprong in three volumes, beginning 12 May

- Ease Auto Group Inc. & Ease Fleet Repair Service Celebrate Grand Opening Charlotte, North Carolina

- Progressive Dental & The Closing Institute Partner with Zest Dental Solutions to Elevate Full-Arch Growth and Patient Outcomes

- CCHR: While Damaging Antipsychotics Win Approval, Proven Non-Drug Alternatives Remain Ignored

- Arcuri Group Announces Long‑Term Partnership with WakeMed Health & Hospitals to Deliver Situational Awareness and De‑escalation Training

- At 25, She Became One of the Youngest AAPI Female Founders to Win One of the World's Most Prestigious Design Awards for a Lamp That Makes You Smile

- Juego Studios Extends Full-Cycle Game Development & Outsourcing Capabilities to the UAE Market

- VENUS Goes Live on CATEX Exchange As UK Financial Ltd Activates The Premier Division Of The Maya Meme's League

- Atlanta Tech Founder Seeks Clarity on Intellectual Property and Innovation Policy

- FPTower Inc. nonprofit launches coastal safety raffle fundraiser

- Purple Heart Recipient Honored by Hall of Fame Son In Viral Tribute Sparking National Conversation on Service Fatherhood, Healing and Legacy

- STEM Agent Academy Mission 01: Reclaiming Children's Curiosity from the Digital Void

- Amicly Launches as a Safety-First Social App Designed to Help People Build Real, Meaningful Friendships

- Primeindexer Google indexing platform launched by SEO Danmark APS

- Kaltra Introduces New Downward-Spraying Distribution Technology to Boost Microchannel Evaporator Performance

- Talentica Announces Winners of Multi-Agent Hackathon 2026

- Special Alert: Undervalued Opportunity: IQSTEL (N A S D A Q: IQST) Positioned for Explosive Multi-Year Growth

- Triple-Digit Growth, Strategic N A S D A Q Uplist, Plus A Scalable Healthcare Rollout Model: Stock Symbol: CDIX